Keer Group packed up some of its yarn-spinning machines, shown in 2013 in China’s

Zhejiang province, and moved them to South Carolina to save on production costs.

“No one could have imagined five years ago that China would look at the cost structure in South Carolina and say it’s more profitable to locate in South Carolina than in China,” says Auggie Tantillo, a South Carolina native who heads the National Council of Textile Organizations.

For years, South Carolina’s business leaders were at loggerheads with China. Roger Milliken, the former chief executive of textile giant Milliken & Co., bankrolled unsuccessful efforts to block China’s entry into the World Trade Organization because he believed Chinese competition would undermine U.S. firms. Former Sen. Jim DeMint, who won office as a free trader, says that many people in his home state believed they were losing their jobs because of low-cost Chinese competition.

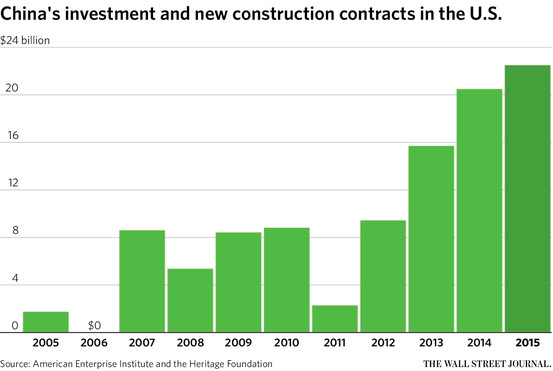

But now Chinese investment in the state, although now at modest levels, is starting to build. Chinese investors are buying golf courses near Myrtle Beach, and setting up yarn, plastic and chemical companies elsewhere. In one of the biggest investments, Chinese-owned Volvo Car Corp. last year said it would invest $500 million to build a new vehicle plant near Charleston.

So far, Chinese firms have invested about $300 million in South Carolina and employ about 1,000, according to Rhodium Group, a New York research group. That’s a small fraction of the approximately 130,000 South Carolina workers who now work for foreign-owned firms in the state, mainly from Germany, France and elsewhere in Europe. South Carolina’s success in snagging foreign investment is the subject of a Wall Street Journal front-page story.

The state has focused on Chinese investment since at least 2001, said John Ling, who until recently headed the state’s Chinese investment efforts. “The breaking point,” Mr. Ling said, was in 2009 when China spent heavily to stimulate its economy and pull itself out of the global recession. Part of Beijing’s strategy was to encourage Chinese companies to invest overseas as a way to build their global presence to find markets for excess supply. The strategy also could boost Chinese exports. That’s because foreign firms generally look to home companies for supplies.

Few in Beijing knew much about South Carolina, Mr. Ling said, and what they heard often didn’t help. “It was always something not good—racial problems, lack of education” and no local Chinese community, Mr. Ling said.

Still, the state had a number of pluses: laid-off manufacturing workers looking for jobs, low wages, the modern Port of Charleston, good roads and a state government willing to give tax breaks and other benefits to foreign firms. “As soon as we sign a company, we custom-build a training program for them,” said the state’s commerce secretary, Robert “Bobby” Hitt.

Even Mr. Ling, though, said he was surprised when Keer Group of Hangzhou, China, said in 2009 that it wanted to build a cotton-yarn firm in South Carolina. “I thought, if the Americans couldn’t figure out how to make money in the textile business (in South Carolina), how could the Chinese do it?” said Mr. Ling, who was born in China but has become a U.S. Citizen.

But Keer executives said they realized that the gap in wages between China and the U.S. was narrowing, plus South Carolina had cheaper land, energy and raw cotton than China. Keer opened its first plant in South Carolina last year and now employs about 180 people, said Lilian Chang, a sales executive at the South Carolina plant. Over time, it wants to add four more factories and build up its workforce to 500.

“What we lack (in South Carolina) is professional technicians” to run the company’s automated spinning machinery, Ms. Chang said. One reason the U.S. textile industry had such big layoffs, economists say, is that the industry became so automated that it needed far fewer workers to run computerized assembly lines.

For some in the Palmetto state, the investment by the state’s one-time archrival is worrying, despite the jobs the companies bring. The Chinese investment “is a sign of weakness,” said Jim Jamborg, a Little River, S.C., postal worker. “The Chinese are coming in and American businesses are moving out.”

Wall Street Journal (blog)

Please

contact us in case of Copyright Infringement of the photo sourced from the internet, we will remove it within 24 hours.